CAS Number 8042-47-5 or 8012-95-1, Light and Heavy Liquid Paraffin or Mineral Oil IP USP NF BP Ph Eur EP Grade Manufacturers Exporters

CAS Number 8042-47-5 or 8012-95-1, Light and Heavy Liquid Paraffin or Mineral Oil IP USP NF BP Ph Eur EP Grade Manufacturer Exporter

For Properties Specifications of Light and Heavy Liquid Paraffin or Mineral Oil Click Properties, Specifications of Light and Heavy Liquid Paraffin or Mineral Oil Manufacturer.

For Uses of Light and Heavy Liquid Paraffin or Mineral Oil Click Uses of Light and Heavy Liquid Paraffin or Mineral Oil Manufacturer.

For For SDS MSDS Sheet of Light and Heavy Liquid Paraffin or Mineral Oil Click SDS Safety Data Sheet MSDS Sheet of Light and Heavy Liquid Paraffin or Mineral Oil Manufacturer.

The Properties and Specifications of Light and Heavy Liquid Paraffin or Mineral Oil:

Specifications of Light Mineral Oil USP NF Grade:

Specifications of Light Liquid Paraffin BP Ph Eur Grade:

DEFINITION

Purified mixture of liquid saturated hydrocarbons obtained from petroleum.

CHARACTERS

Appearance: Colourless, transparent, oily liquid, free from fluorescence in daylight.

Solubility: Practically insoluble in water, slightly soluble in ethanol (96 per cent), miscible with hydrocarbons.

IDENTIFICATION

First identification: A, C

Second identification: B, C

A. Infrared absorption spectrophotometry.

Comparison Ph. Eur. reference spectrum of liquid paraffin.

B. In a test tube cautiously boil 1 mL with 1 mL of 0.1 M sodium hydroxide, with continuous shaking, for about 30 s. On cooling to room temperature, 2 phases separate. To the aqueous phase add 0.1 mL of phenolphthalein solution. The solution becomes red.

C. Viscosity.

TESTS

Acidity or alkalinity: To 10 mL add 20 mL of boiling water and shake vigorously for 1 min. Separate the aqueous layer and filter. To 10 mL of the filtrate, add 0.1 mL of phenolphthalein solution. The solution is colourless. Not more than 0.1 mL of 0.1 M sodium hydroxide is required to change the colour of the indicator to pink.

Relative density: 0.810 to 0.875.

Viscosity: 25 mPa⋅s to 80 mPa⋅s.

Polycyclic aromatic hydrocarbons: To pass the test.

Readily carbonisable substances: To pass the test.

Solid paraffins: Dry a suitable quantity of the substance to be examined by heating at 100C for 2 h and cool in a desiccator over sulfuric acid. Place in a glass tube with an internal diameter of about 25 mm, close the tube and immerse in a bath of iced water. After 4 h, the liquid is sufficiently clear for a black line, 0.5 mm wide, to be easily seen against a white background held vertically behind the tube.

Specifications of Liquid Paraffin BP Ph Eur Grade:

Action and use: Faecal softener.

DEFINITION

Purified mixture of liquid saturated hydrocarbons obtained from petroleum.

CHARACTERS

Appearance: Colourless, transparent, oily liquid, free from fluorescence in daylight.

Solubility: Practically insoluble in water, slightly soluble in ethanol (96 per cent), miscible with hydrocarbons.

IDENTIFICATION

First identification: A, C

Second identification: B, C

A. Infrared absorption spectrophotometry.

Comparison Ph. Eur. reference spectrum of liquid paraffin.

B. In a test tube cautiously boil 1 mL with 1 mL of 0.1 M sodium hydroxide, with continuous shaking, for about 30 s. On cooling to room temperature, 2 phases separate. To the aqueous phase add 0.1 mL of phenolphthalein solution. The solution becomes red.

C. Viscosity.

TESTS

Acidity or alkalinity: To 10 mL add 20 mL of boiling water and shake vigorously for 1 min. Separate the aqueous layer and filter. To 10 mL of the filtrate, add 0.1 mL of phenolphthalein solution. The solution is colourless. Not more than 0.1 mL of 0.1 M sodium hydroxide is required to change the colour of the indicator to pink.

Relative density: 0.827 to 0.890.

Viscosity: 110 mPa⋅s to 230 mPa⋅s.

Polycyclic aromatic hydrocarbons: To pass the test.

Readily carbonisable substances: To pass the test.

Solid paraffins: Dry a suitable quantity of the substance to be examined by heating at 100C for 2 h and cool in a desiccator over sulfuric acid. Place in a glass tube with an internal diameter of about 25 mm, close the tube and immerse in a bath of iced water. After 4 h, the liquid is sufficiently clear for a black line, 0.5 mm wide, to be easily seen against a white background held vertically behind the tube.

Specifications of Mineral Oil, White BP Ph Eur Grade:

Liquid Petrolatum; Liquid Paraffin

CAS 8042-47-5

DESCRIPTION

Mineral Oil, White, occurs as a colorless, transparent, oily liquid, free or nearly free from fluorescence. It is a mixture of refined liquid hydrocarbons, essentially paraffinic and naphthenic in nature, obtained from petroleum by solvent extraction and/or crystallization with subsequent purification by acid treatment and/or hydrogen treatment. It has an initial boiling point above 200C. Its average molecular weight is not less than 300. Its minimum carbon number at 5% distillation is 17. It is insoluble in water and in alcohol, is soluble in volatile oils, and is miscible with most fixed oils, but not with castor oil. It may contain any antioxidant permitted in food by the U.S. Food and Drug Administration, in an amount not greater than that required to produce its intended effect.

Function: Defoaming agent; lubricant; release agent; protective coating; glazing agent; sealing agent.

REQUIREMENTS

Lead: Not more than 1 mg/kg.

Readily Carbonizable Substances: Passes test.

Specific Gravity: Not less than that stated, or within the range claimed by the vendor.

Ultraviolet Absorbance: (polynuclear hydrocarbons) Passes test.

Viscosity: Not less than 3 centistokes at 100C.

DEFINITION

Light Mineral Oil is a purified mixture of liquid hydrocarbons obtained from petroleum. It may contain a suitable stabilizer.

IDENTIFICATION

A. Infrared Absorption

B. It meets the requirements in Specific Tests for Viscosity—Capillary Methods.

Limit of Polycyclic Aromatic Hydrocarbons:

To pass the test.

Acceptance criteria: The absorbance at any wavelength in the specified range of the Sample solution is NMT one-third of the absorbance of the Standard solution.

Specific Gravity: 0.818–0.880

Viscosity Capillary Methods:3.0–34.4 mm2/s for kinematic viscosity, measured with a capillary viscometer at 40 ± 0.1C

Acidity:

Sample solution: Combine 10 mL of Light Mineral Oil and 20 mL of boiling water, shake vigorously for 1 min, and allow to cool. Remove, and filter the aqueous layer.

Analysis: To 10 mL of the Sample solution add 0.1 mL of phenolphthalein.

Acceptance criteria: The solution does not produce a pink color. NMT 1.0 mL of 0.01 N sodium hydroxide is required to produce a pink color.

Readily Carbonizable Substances Test:

To pass the test.

Solid Paraffin:

Sample: Light Mineral Oil that has been dried previously in a beaker at 105c for 2 h and cooled to room temperature in a desiccator over silica gel

Analysis: Fill a tall, cylindrical, standard oil-sample bottle of colorless glass of 120-mL capacity with the Sample. Insert the stopper, and immerse the bottle in a mixture of ice and water for 4 h.

Acceptance criteria: The Sample is sufficiently clear that a black line 0.5 mm in width, on a white background, held vertically behind the bottle, is clearly visible.

Limit of Sulfur Compounds:

Solution A: Saturated solution of lead(II) oxide in sodium hydroxide (200 mg/mL)

Sample: 4.0 mL

Analysis: Combine the Sample, 2 mL of dehydrated alcohol, and 2 drops of Solution A, heat at 70C for 10 min with frequent shaking, and cool.

Acceptance criteria: No dark brown color develops.

Specifications of Mineral Oil USP Grade:

DEFINITION

Mineral Oil is a purified mixture of liquid hydrocarbons obtained from petroleum. It may contain a suitable stabilizer.

IDENTIFICATION

A. Infrared Absorption

B. It meets the requirements in Specific Tests for Viscosity—Capillary Methods.

Limit of Polycyclic Aromatic Hydrocarbons:

To pass the test.

Acceptance criteria: The absorbance at any wavelength in the specified range of the Sample solution is NMT one-third of the absorbance of the Standard solution.

Specific Gravity: 0.845–0.905

Viscosity Capillary Methods: 34.5–150.0 mm2 ·s –1 for kinematic viscosity, measured with a capillary viscometer at 40 ± 0.1C.

Acidity:

Sample: 10 mL

Analysis: Add 20 mL of boiling water to the Sample, and shake vigorously for about 1 min. Allow to cool, and draw off the separated water. To 10 mL of the filtered aqueous layer add 0.1 mL of phenolphthalein.

Acceptance criteria: The solution does not produce a pink color. NMT 1.0 mL of 0.01 N sodium hydroxide is required to produce a pink color.

Readily Carbonizable Substances Test:

To pass the test.

Acceptance criteria: The oil portion of the Sample may turn hazy, but it remains colorless or shows a slight pink or yellow color, and the acid portion of the Sample does not become darker than the Standard solution.

Solid Paraffin:

Sample: Mineral Oil that has been dried previously in a beaker at 105C for 2 h and cooled to room temperature in a desiccator over silica gel

Analysis: Fill a tall, cylindrical, standard oil-sample bottle of colorless glass of 120-mL capacity with the Sample, insert the stopper, and immerse in an ice bath for 4 h.

Acceptance criteria: The Sample is sufficiently clear that a black line 0.5 mm in width, on a white background, held vertically behind the bottle, is clearly visible.

Limit of Sulfur Compounds:

Solution A: Saturated solution of lead(II) oxide in sodium hydroxide (200 mg/mL)

Sample: 4.0 mL

Analysis: Combine the Sample, 2 mL of dehydrated alcohol, and 2 drops of Solution A, heat at 70C for 10 min with frequent shaking, and cool.

Acceptance criteria: No dark brown color develops.

We also manufacture Paraffin Light Liquid IP EP Grade.

The Uses of Light and Heavy Liquid Paraffin or Mineral Oil:

Paraffin oil and paraffin wax have found a wide range of industrial, medical, as well as cosmetic uses. Liquid paraffin oil usually comes in two forms, heavy liquid paraffin oil and light liquid paraffin oil. It is is a very highly refined mineral oil used in cosmetics and medicine. Liquid paraffin is a hydrating and cleansing agent. Hence, it is used in several cosmetics.

The MSDS-SDS Hazard Statement of Light and Heavy Liquid Paraffin or Mineral Oil:

Light and Heavy Liquid Paraffin, Light Mineral Oil and Mineral Oil SDS, Safety Data Sheet

MSDS Sheet, Material Safety Data Sheet 24-Nov-24

Section 1: Chemical Product and Company Identification

Product Name & Other Names: Light and Heavy Liquid Paraffin, Light Mineral Oil and Mineral Oil

CAS Number: 8042-47-5 or 8012-95-1

EINECS EC Number: 232-455-8 or 232-384-2

Relevant uses and uses advised against (if any): Industrial Manufacturing

Section 2: Hazards Identification

GHS, Globally Harmonized System Classification in accordance with 29 CFR 1910

Classification according to Regulation (EC) No 1272/2008

Not a hazardous substance or mixture according to Regulation (EC) No. 1272/2008.

This substance is not classified as dangerous according to Directive 67/548/EEC.

Labeling according to GHS & Regulation (EC) No 1272/2008

GHS Label Elements NONE |

Signal Word: None

Precautionary statements:

P261: Avoid breathing dust/fume/gas/mist/vapors/spray.

P262: Do not get in eyes, on skin, or on clothing.

P281: Use personal protective equipment as required.

P302+P352: IF ON SKIN: Wash with plenty of soap and water.

P304+P340: IF INHALED: Remove victim to fresh air and keep at rest in a position comfortable for breathing.

P305+P351+P338: IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing.

P337+313: If eye irritation persists get medical advice/attention.

Section 3: Composition and Information on Ingredients

Product Name & Other Names: Light and Heavy Liquid Paraffin, Light Mineral Oil and Mineral Oil

CAS Number: 8042-47-5 or 8012-95-1

EINECS EC Number: 232-455-8 or 232-384-2

Section 4: First Aid Measures

Always seek medical advice after the first aid treatment.

Skin: Rinse with water. Soap may be used. Seek Medical Aid.

Eyes: Wash eyes with plenty of water for at least 15 minutes, lifting lids occasionally. Seek Medical Aid.

Inhalation: Remove to fresh air. If not breathing, give artificial respiration. If breathing is difficult, give oxygen.

Ingestion: If swallowed, induce vomiting immediately after giving two glasses of water. Never give anything by mouth to an unconscious person.

Notes to Physician: Treat symptomatically.

Section 5: Fire and Explosion Data

Flammability of the Product: Combustible.

Products of Combustion: Fumes and Oxides of carbon.

Fire Fighting Media and Instructions: Use water spray, alcohol-resistant foam, dry chemical or carbon dioxide. Sand may also be used. Avoid water with full jet.

Section 6: Accidental Release Measures

Personal precautions, protective equipment and emergency procedures: Avoid breathing dust/fumes/gas/mist/vapors/spray. Ensure adequate ventilation. Use individual protective equipment (waterproof boots, suitable protective clothing, safety glasses, etc.).

Environmental precautions: Do not let the product enter drains, soil or water sources.

Methods and materials used for containment Cleanup procedures and Storage:

Small Spill: Use appropriate tools to put the spilled solid in a convenient waste disposal container.

Large Spill: Contain spilled material. Do not inhale vapors, mist, or gas. Avoid dust formation. Cover with an inert, non-combustible absorbent material, (e.g. sand, earth, diatomaceous earth, vermiculite). Vacuum or sweep-up and remove to an approved disposal container. Use a shovel to put the material into a convenient waste disposal container.

Section 7: Handling and Storage

Precautions for safe handling: This material may burn but will not ignite readily. Keep all sources of ignition away Apply according to good manufacturing and industrial hygiene practices. Ensure proper ventilation. Wash thoroughly after handling. Do not drink, eat or smoke while handling. Avoid contact with skin, eyes and clothing. Minimize dust generation. Avoid breathing dust/fumes/gas/mist/vapors/spray. Keep container tightly closed. Avoid ingestion and inhalation. Use individual protective equipment (waterproof boots, suitable protective clothing, safety glasses, etc.).

Conditions for safe storage, including any incompatibilities: Store in cool, dry and ventilated area away from heat sources and protected from sunlight in tightly closed original container. Keep air contact to a minimum. Do not leave the material container open. Store protected from heat, sparks and ignition sources and incompatible materials. Avoid inhalation of dust/mist/vapor. Do not store with incompatible materials like oxidizing agents.

Section 8: Exposure Controls/Personal Protection

Occupational Exposure Limit:

ACGIH TLV (United States) TWA 5mg/m3 for 8 hours.

OSHA PEL (United States, 2/2013). TWA: 5 mg/m3 for 8 hours.

Engineering Controls: Use process enclosures, local exhaust ventilation, or other engineering controls to keep airborne levels LOW.

Personal Protection: Safety glasses. Lab coat. Dust respirator. Be sure to use an approved/certified respirator or equivalent Gloves.

Personal Protection in Case of a Large Spill: Splash goggles. Full suit. Dust respirator. Boots. Gloves. A self-contained breathing apparatus should be used to avoid inhalation of the product.

Section 9: Physical and Chemical Properties

Physical state and appearance: Transparent, colorless, odorless and tasteless oil.

Odor: None.

Odor threshold: Not APPLICABLE.

pH: No data found.

Relative density: Varies.

Boiling Point: No data found..

Melting Point: Varies.

Flash point: No data found.

Auto-ignition temperature: No data found.

Decomposition temperature: No data found.

Upper/lower flammability or explosive limits: No data found.

Vapor pressure: No data found.

Vapor density: No data found.

Evaporation rate: No data found.

Flammability (solid, gas): No data found.

Partition coefficient: n-octanol/water: No data found.

Solubility: Insoluble in water.

Viscosity: Not available.

Section 10: Stability and Reactivity Data

Stability: It is stable.

Conditions of instability: Incompatible materials

Incompatibility with various substances: Heat, light, strong oxidizing agents.

Polymerization: Will not occur.

Section 11: Toxicological Information

Toxicity to Animals:

LD50 Oral: > 5000 mg/kg ( Rat )

LC50 Inhalation: >2000 ppm ( Rat ) 4 h.

Carcinogenic Effects: Not a reported carcinogen by IARC, NTP, ACGIH, OSHA.

Mutagenic Effects: No data found.

Developmental Toxicity: No data found.

Reproductive Effects: No data found.

Section 12: Ecological Information

LC50 Fish: LC50: > 10000 mg/L, 96h (Lepomis macrochirus).

Ecotoxicity: The product is not considered harmful to aquatic organisms or to cause long-term adverse effects in the environment. Not dangerous for the ozone layer.

Persistence and Degradability: No data found.

Mobility: No data found.

Bioaccumulation/ Accumulation: No data found.

Results of PBT and vPvB assessment: No data found for assessment.

Section 13: Disposal Considerations

Waste Disposal: Waste must be disposed of in accordance with federal, state and local environmental control regulations. Follow all the pollution control rules.

Section 14: Transport Information

DOT (US): Not regulated.

IMDG: Not regulated.

IATA: Not regulated.

Section 15: Other Regulatory Information

USA Federal and State Regulations:

SARA 311/312 Hazards: See section 2.

Section 16 - Additional Information

DISCLAIMER: The information and recommendations set forth herein are presented in good faith and believed correct as of the date hereof. It is compiled from various sources and it is not necessarily all inclusive nor fully adequate in every circumstance. In addition, these suggestions should not be confused with nor followed in violation of applicable laws, regulations, rules or insurance requirements applicable. This MSDS sheet is intended only as a guide to the appropriate precautionary handling of the material by a professionally trained person using this product. Individuals receiving the information must exercise their independent judgment in determining its appropriateness for a particular purpose.Anmol Chemicals & Pharmaceuticals Pvt. Ltd. is an off-shoot of Anmol Chemicals Taloja. It is located in MIDC Taloja and it is manufacturing pharmaceutical grades of API, Excepients, Food grade and Reagent grade chemicals. Anmol Chemicals & Pharmaceuticals Pvt. Ltd. is a several decades old group of companies, engaged in manufacturing, supplying, distributing, wholesale supplies for actual users, retail or small pack supplies for research and development chemicals, fine and speciality chemicals, pharmaceutical excipients, mineral fortifiers in chemically pure, Analytical reagent grade, IP BP USP Ph Eur EP JP and other pharmaceutical grade monograph including FCC Food grade chemicals and Nutraceuticals, Mineral Fortifiers at best prices.

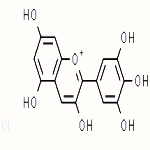

Light Liquid Paraffin or Mineral Oil approximate Structure

CAS Number 8042-47-5 or 8012-95-1, Light and Heavy Liquid Paraffin or Mineral Oil Manufacturer Exporter

ANMOL CHEMICALS & PHARMACEUTICALS Pvt. Ltd.

India, USA, Europe, UAE

TELEPHONE: +912223770100

Navi Mumbai, INDIA

e-mail: info(At the rate i.e. @)anmol.org

Copyright. 11-dec-24

We manufacture: