CAS Number 90-80-2, Gluconolactone or Glucono Delta-Lactone or D-Gluconolactone USP Food Grade Manufacturers Exporters

CAS Number 90-80-2, Gluconolactone or Glucono Delta-Lactone or D-Gluconolactone Manufacturer Exporter

For Properties Specifications of Gluconolactone or Glucono Delta-Lactone Click Properties, Specifications of Gluconolactone or Glucono Delta-Lactone Manufacturer.

For Uses of aaa Click Uses of aaa Manufacturer.

For For SDS MSDS Sheet of Gluconolactone or Glucono Delta-Lactone Click SDS Safety Data Sheet MSDS Sheet of Gluconolactone or Glucono Delta-Lactone Manufacturer.

The Properties and Specifications of Gluconolactone or Glucono Delta-Lactone:

Gluconolactone USP Grade Specifications

C6H10O6 -- 78.14

D-Gluconic acid -lactone.

Glucono delta-lactone [CAS 90-80-2].

Gluconolactone contains not less than 99.0 percent and not more than 101.0 percent of C6H10O6.

Identification: Dissolve about 0.5 g in 5 mL of warm water in a test tube. Add 1 mL of freshly distilled phenylhydrazine, and heat on a steam bath for 30 minutes. Cool the solution, induce crystallization by scratching the inner surface of the test tube with a glass rod, and collect the crystals of the phenylhydrazide of gluconic acid. Dissolve the crystals in 10 mL of hot water to which a small amount of activated charcoal has been added, filter, recrystallize, wash the crystals with 2 mL of cold water, and dry the crystals at 105 for 1 hour: the crystals so obtained melt between 195C and 200C.

Lead: ---: the limit is 0.001%.

Heavy metals: ---: the limit is 0.002%.

Reducing substances: Transfer 10.0 g to a 400-mL beaker, add 40 mL of water, and swirl to dissolve. Add 2 drops of PhPh, and neutralize with sodium hydroxide solution (1 in 2). Dilute with water to about 50 mL, and add 50 mL of alkaline cupric tartrate. Heat so that the solution begins to boil in 4 minutes, and allow boiling to continue for 120 seconds. Pass the suspension through a medium-porosity filtering crucible, and wash the filter with three 5-mL portions of water. Place the crucible in an upright position in the original beaker, add 5 mL of water and 3 mL of nitric acid to the crucible, mix with a glass rod to ensure complete solution of the cuprous oxide, and wash the solution from the crucible into a beaker with the aid of 5 mL of water. Add bromine, usually 5 to 10 mL, until the solution becomes yellow in color, and dilute with water to about 75 mL. Add a few glass beads, boil until the bromine has been driven off, and cool. Slowly add ammonium hydroxide until a deep blue color appears, then adjust with glacial acetic acid to a pH of 4, and add water to make about 100 mL. Add 4 g of potassium iodide, and titrate with 0.1 N sodium thiosulfate, adding starch just before the endpoint is reached: not more than 16.1 mL of 0.1 N sodium thiosulfate is consumed.

The Uses of Gluconolactone or Glucono Delta-Lactone:

Gluconolactone is a polyhydroxy acid used in the dissolution of calculi and used as an additive in various drug products to maintain consistency and other characteristics. Gluconolactone is a naturally-occurring food additive used as a sequestrant, an acidifier, or a curing, pickling, or leavening agent. It is meant to be used daily to help brighten dull skin, fade dark spots, and even combat blackheads and clogged pores. Gluconolactone is a preservative, but it is also a humectant and a solvent. Glucono delta-lactone, also known as gluconolactone, is a food additive with the E number E575 used as a sequestrant, an acidifier, or a curing, pickling, or leavening agent.

The MSDS-SDS Hazard Statement of Gluconolactone or Glucono Delta-Lactone:

Gluconolactone or D-Gluconolactone or Glucono delta-lactone SDS, Safety Data Sheet

MSDS Sheet, Material Safety Data Sheet 11-Jan-23

Section 1: Chemical Product and Company Identification

Product Name & Other Names: Gluconolactone or D-Gluconolactone or Glucono delta-lactone.

CAS Number: 90-80-2

EINECS EC Code: 202-016-5

Chemical Formula: C6H10O6

Molecular Weight: 178.14

Relevant uses and uses advised against (if any): Industrial Manufacturing.

Section 2: Hazards Identification

GHS, Globally Harmonized System Classification in accordance with 29 CFR 1910

Hazard Class and Category Code(s), Regulation (EC) No 1272/2008 (CLP)

Not a hazardous substance or mixture according to Regulation (EC) No. 1272/2008.

This substance is not classified as dangerous according to Directive 67/548/EEC.

Labeling Regulation EC 1272/2008 (CLP) & GHS

GHS Label Elements NONE |

Signal Word: None

Precautionary statements:

P261: Avoid breathing dust/fume/gas/mist/vapors/spray.

P262: Do not get in eyes, on skin, or on clothing.

P281: Use personal protective equipment as required.

P302+P352: IF ON SKIN: Wash with plenty of soap and water.

P304+P340: IF INHALED: Remove victim to fresh air and keep at rest in a position comfortable for breathing.

P305+P351+P338: IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing.

P337+313: If eye irritation persists get medical advice/attention.

Section 3: Composition and Information on Ingredients

Product Name & Other Names: Gluconolactone or D-Gluconolactone or Glucono delta-lactone.

CAS Number: 90-80-2

EINECS EC Code: 202-016-5

Section 4: First Aid Measures

Always seek medical advice after the first aid treatment.

Skin: Rinse with water. Soap may be used. Seek Medical Aid.

Eyes: Wash eyes with plenty of water for at least 15 minutes, lifting lids occasionally. Seek Medical Aid.

Inhalation: Remove to fresh air. If not breathing, give artificial respiration. If breathing is difficult, give oxygen.

Ingestion: If swallowed, induce vomiting immediately after giving two glasses of water. Never give anything by mouth to an unconscious person.

Notes to Physician: Treat symptomatically.

Section 5: Fire and Explosion Data

Flammability of the Product: Non-flammable. Combustible in presence of heat. Fine dust dispersed in air in sufficient concentrations, and in the presence of an ignition source is a potential dust explosion hazard.

Products of Combustion: Fumes and Oxides of Carbon.

Fire Fighting Media and Instructions: Use water spray, alcohol-resistant foam, dry chemical or carbon dioxide. Wear self-contained breathing apparatus for firefighting if necessary.

Special Information: In the event of a fire, wear full protective clothing and NIOSH-approved self-contained breathing apparatus with full face piece operated in the pressure demand or other positive pressure mode. At high temperatures under fire conditions, it may produce toxic or irritating fumes.

Section 6: Accidental Release Measures

Personal precautions, protective equipment, and emergency procedures: Avoid breathing dust/fumes/gas/mist/vapors/spray. Use individual protective equipment (waterproof boots, suitable protective clothing, safety glasses, etc). Do not approach facing the wind.

Environmental precautions: Do not let the product enter drains, soil or water sources.

Methods and materials used for containment Cleanup procedures and Storage: Contain spilled material. Do not inhale vapors, mist, or gas. Avoid dust formation. Use a shovel to put the material into a convenient waste disposal container. Finish cleaning by spreading water on the contaminated surface and dispose of according to legal requirements.

Section 7: Handling and Storage

Precautions for safe handling: Apply according to good manufacturing and industrial hygiene practices. Ensure proper ventilation. Wash thoroughly after handling. Do not drink, eat, or smoke while handling. Avoid contact with skin, eyes, and clothing. Minimize dust generation. Avoid breathing dust/fumes/gas/mist/vapors/spray.Keep container tightly closed. Avoid ingestion and inhalation. Use individual protective equipment (waterproof boots, suitable protective clothing, safety glasses, etc). Prevent any contact with hot surfaces. Keep away from sources of ignition. Ground all equipment containing material.

Conditions for safe storage, including any incompatibilities: Moisture sensitive. Store in cool, dry, and ventilated area away from heat sources and protected from sunlight in tightly closed original container. Keep air contact to a minimum. Do not leave the material container open. Store protected from heat, sparks and ignition sources and incompatible materials. Avoid contact with skin and eyes. Avoid inhalation of dust/mist/vapor. Do not store with incompatible materials like strong oxidizing agents, acids, and alkalis.

Section 8: Exposure Controls/Personal Protection

Engineering Controls: Use process enclosures, local exhaust ventilation, or other engineering controls to keep airborne levels below recommended exposure limits.

Ventilation System: A system of local and/or general exhaust is recommended to keep employee exposures as low as possible.

Personal Respirators (NIOSH Approved): For conditions of use where exposure to dust or mist is apparent and engineering controls are not feasible, a particulate respirator may be worn.

Skin Protection: Wear protective gloves and clean body-covering clothing.

Eye Protection: Use chemical safety goggles and/or full face shield where dusting or splashing of solutions is possible. Maintain eye wash fountain and quick-drench facilities in work area.

Other Control Measures: Maintain good housekeeping in work area. Handle in accordance with good industrial hygiene and safety practice.

Section 9: Physical and Chemical Properties

Physical state and appearance: Solid. White powder or crystals.

Odor: Not available.

Odor threshold: Not available.

pH: Not available.

Relative density: Not available.

Melting point/freezing point: 153C to 160C

Initial boiling point and boiling range: Not available.

Flash point: Not available.

Auto-ignition temperature: Not available.

Decomposition temperature: Not available.

Upper/lower flammability or explosive limits: Not available.

Vapor pressure: Not available.

Vapor density: Not available.

Evaporation rate: Not available.

Flammability (solid, gas): Not available.

Partition coefficient: n-octanol/water: Not available.

Solubility: Soluble in water.

Viscosity: Not available.

Section 10: Stability and Reactivity Data

Stability: It is stable in room temperature in closed containers under normal storage & handling.

Conditions of instability: Incompatible materials, Moisture, Light.

Incompatibility with various substances: Avoid high temperatures, sparks, open flames and moisture, light. Avoid contact with strong oxidizing agents, acids, and alkalis.

Polymerization: Will not occur.

Section 11: Toxicological Information

LD50 Oral - Rat - Not available.

Carcinogenic Effects: Not a reported carcinogen by IARC NTP ACGIH OSHA.

Mutagenic Effects: Not available.

Teratogenic Effects: Not available.

Developmental Toxicity: Not available.

Section 12: Ecological Information

Toxicity to fish: Not available.

Products of Biodegradation: Possibly hazardous short-term degradation products are not likely. However, long term degradation products may arise.

Persistence and degradability: No data available.

Bioaccumulative potential: No data available.

Section 13: Disposal Considerations

Waste Disposal: Waste must be disposed of in accordance with federal, state, and local environmental control regulations.

Section 14: Transport Information

DOT USA & TDG Canada: Not controlled.

IMDG: Not controlled.

IATA: Not controlled.

ADR/RID Europe: Not controlled.

Section 15: Other Regulatory Information

USA Regulations:

SARA 311/312 Hazards: No SARA Hazards

California Prop 65: Not listed.

Disclaimer:

**************************

Our company provides this MSDS sheet in good faith but makes no representation as to its comprehensiveness or accuracy. This SDS sheet is intended only as a guide to the appropriate precautionary handling of the material by a properly trained person using this product. The above information has been compiled from various sources and has the possibility of discrepancy and being out-dated information. Individuals receiving the information must exercise their independent judgment and do further search in determining its appropriateness for a particular purpose. In no case shall our company be liable to loss or damages by the product user.

**************************

Anmol Chemicals & Pharmaceuticals Pvt. Ltd. is an off-shoot of Anmol Chemicals Taloja. It is located in MIDC Taloja and it is manufacturing pharmaceutical grades of API, Excepients, Food grade and Reagent grade chemicals. Anmol Chemicals & Pharmaceuticals Pvt. Ltd. is a several decades old group of companies, engaged in manufacturing, supplying, distributing, wholesale supplies for actual users, retail or small pack supplies for research and development chemicals, fine and speciality chemicals, pharmaceutical excipients, mineral fortifiers in chemically pure, Analytical reagent grade, IP BP USP Ph Eur EP JP and other pharmaceutical grade monograph including FCC Food grade chemicals and Nutraceuticals, Mineral Fortifiers at best prices.

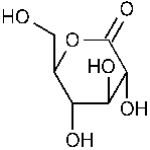

Gluconolactone or Glucono Delta-Lactone Structure

CAS Number 90-80-2, Gluconolactone or Glucono Delta-Lactone or D-Gluconolactone Manufacturer Exporter

ANMOL CHEMICALS & PHARMACEUTICALS Pvt. Ltd.

India, USA, Europe, UAE

TELEPHONE: +912223770100

Navi Mumbai, INDIA

e-mail: info(At the rate i.e. @)anmol.org

Copyright. 11-dec-24

We manufacture:

Glacial Acetic Acid Manufacturer