CAS Number 1592-23-0, Calcium Stearate USP NF BP Ph Eur FCC Food Grade Manufacturers Exporters

CAS Number 1592-23-0, Calcium Stearate Manufacturer Exporter

For Properties Specifications of Calcium Stearate Click Properties, Specifications of Calcium Stearate Manufacturer.

For Uses of Calcium Stearate Click Uses of Calcium Stearate Manufacturer.

For For SDS MSDS Sheet of Calcium Stearate Click SDS Safety Data Sheet MSDS Sheet of Calcium Stearate Manufacturer.

The Properties and Specifications of Calcium Stearate:

Calcium Stearate USP NF Grade Specifications

Stearic Acid Calcium Salt

Octadecanoic acid, calcium salt.

Calcium stearate CAS 1592-23-0

Calcium Stearate is a compound of calcium with a mixture of solid organic acids obtained from fats and consists chiefly of variable proportions of calcium stearate and calcium palmitate. It contains the equivalent of not less than 9.0 percent and not more than 10.5 percent of calcium oxide (CaO).

Identification:

A: Heat 1 g Calcium Stearate with a mixture of 25 mL of water and 5 mL of hydrochloric acid: fatty acids are liberated and appear as an oily layer floating on the surface of the liquid. The water layer responds to the tests for Calcium.

B: Mix 25 g Calcium Stearate with 200 mL of hot water, add 60 mL of 2 N sulfuric acid, and heat the mixture, with frequent stirring, until the separated fatty acid layer is clear. Wash the fatty acids with boiling water until free from sulfate, collect them in a small beaker, and warm on a steam bath until the water has separated and the fatty acids are clear. Allow the acids to cool, pour off the water layer, melt the acids, filter into a dry beaker, and dry at 105 for 20 minutes: the fatty acids so obtained congeal at a temperature not below 54.

Loss on drying: Dry it at 105 to constant weight, using 2-hour increments of heating: it loses not more than 4.0% of its weight.

Heavy metals: The limit is 10 µg per g.

Calcium Stearate BP Ph Eur Grade Specifications

Stearic Acid Calcium Salt

Action and use: Excipient.

DEFINITION

Mixture of calcium salts of different fatty acids consisting mainly of stearic octadecanoic acid [(C17H35COO)2Ca; M r 607] and palmitic (hexadecanoic) acid [(C15H31COO)2Ca; M r 550.9] with minor proportions of other fatty acids.

Content:

calcium: 6.4 per cent to 7.4 per cent (dried substance),

stearic acid in the fatty acid fraction: minimum 40.0 per cent,

sum of stearic acid and palmitic acid in the fatty acid fraction: minimum 90.0 per cent.

CHARACTERS

Appearance: Fine, white or almost white, crystalline powder.

Solubility: Practically insoluble in water and in ethanol (96 per cent).

IDENTIFICATION

First identification C, D.

Second identification A, B, D.

A. Freezing point: Minimum 53C, for the residue obtained in the preparation of solution S (see Tests).

B. Acid value: 95 to 210.

C. Examine the chromatograms obtained in the test for fatty acid composition.

Results The retention times of the principal peaks in the chromatogram obtained with the test solution are approximately the same as those of the principal peaks in the chromatogram obtained with the reference solution.

D. Neutralize 5 ml of solution S to red litmus paper R using strong sodium hydroxide solution: The solution gives reaction of calcium.

TESTS

Solution S: To 5.0 g of Calcium Stearate add 50 ml of peroxide-free ether, 20 ml of dilute nitric acid and 20 ml of distilled water. Boil under a reflux condenser until dissolution is complete. Allow to cool. In a separating funnel, separate the aqueous layer and shake the ether layer with 2 quantities, each of 5 ml, of distilled water. Combine the aqueous layers, wash with 15 ml of peroxide-free ether and dilute the aqueous layer to 50 ml with distilled water (solution S). Evaporate the ether layer to dryness and dry the residue at 100-105C. Keep the residue for identification tests A and B.

Acidity or alkalinity: To 1.0 g Calcium Stearate add 20 ml of carbon dioxide-free water and boil for 1 min with continuous shaking. Cool and filter. To 10 ml of the filtrate add 0.05 ml of bromothymol blue solution.

Not more than 0.5 ml of 0.01 M hydrochloric acid or 0.01 M sodium hydroxide is required to change the colour of the indicator.

Chlorides: Maximum 0.1 per cent.

Sulphates: Maximum 0.3 per cent.

Cadmium: Maximum 3.0 ppm.

Atomic absorption spectrometry: To pass the test

Lead: Maximum 10.0 ppm.

Nickel: Maximum 5.0 ppm.

Loss on drying: Maximum 6.0 per cent, determined on 1.000 g by drying in an oven at 105C.

Microbial contamination: Total viable aerobic count (2.6.12) not more than 103 micro-organisms per gram determined by plate count. It complies with the test for Escherichia coli.

Calcium Stearate FCC Food Grade Specifications

Stearic Acid Calcium Salt

CAS 1592-23-0

DESCRIPTION

Calcium Stearate occurs as a fine, white to yellow-white, bulky powder. It is a compound of calcium with a mixture of solid organic acids obtained from edible sources and consists chiefly of variable proportions of calcium stearate and calcium palmitate. It is unctuous and free from grittiness. It is insoluble in water, in alcohol, and in ether.

Function: Ant caking agent; binder; emulsifier.

REQUIREMENTS

Identification

A. Heat 1 g of Calcium Stearate with a mixture of 25 mL of water and 5 mL of hydrochloric acid. Fatty acids are liberated, floating as an oily layer on the surface of the liquid. The water layer gives positive tests for Calcium.

B. Mix 25 g of Calcium Stearate with 200 mL of hot water, then add 60 mL of 2 N sulfuric acid, and heat the mixture, while stirring frequently, until the fatty acids separate cleanly as a transparent layer. Wash the fatty acids with boiling water until free from sulfate, collect them in a small beaker, and warm them on a steam bath until the water has separated and the fatty acids are clear. Allow the acids to cool, pour off the water layer, then melt the acids, filter into a dry beaker, and dry at 105C for 20 min. The solidification point of the fatty acids so obtained is not below 54

Assay: Not less than 9.0% and not more than 10.5% of CaO, calculated on the dried basis.

Free Fatty Acids (as stearic acid): Not more than 3.0%.

Lead: Not more than 2 mg/kg.

Loss on Drying: Not more than 4.0%.

The Uses of Calcium Stearate:

Calcium stearate is primarily used as an acid scavenger, release agent and lubricant in the plastics industry, for waterproofing in construction, and as an anti-caking additive in pharmaceuticals and cosmetics. Calcium stearate is an indirect food additive for use as a component of resinous and polymeric coatings. It is used as a mold-release agent for pharmaceutical tablets and capsules, as an anti-caking agent in cosmetics and as a thickener in lubricants and greases.

The MSDS-SDS Hazard Statement of Calcium Stearate:

Calcium Stearate SDS Safety Data Sheet

MSDS Sheet, Material Safety Data Sheet 09-Jan-23

Section 1: Chemical Product and Company Identification

Product Name & Other Names: Calcium stearate.

CAS Number: 1592-23-0

EINECS EC Number: 216-472-8

Chemical Formula: C36H70CaO4

Molecular Weight: 607.02

Relevant uses and uses advised against (if any): Laboratory and Industrial Manufacturing.

Section 2: Hazards Identification

GHS, Globally Harmonized System Classification in accordance with 29 CFR 1910

Classification according to Regulation (EC) No 1272/2008

Not a hazardous substance or mixture according to Regulation (EC) No. 1272/2008.

This substance is not classified as dangerous according to Directive 67/548/EEC.

Labeling according to GHS & Regulation (EC) No 1272/2008

GHS Label Elements NONE |

Signal Word: None

Precautionary statements:

P261: Avoid breathing dust/fume/gas/mist/vapors/spray.

P262: Do not get in eyes, on skin, or on clothing.

P281: Use personal protective equipment as required.

P302+P352: IF ON SKIN: Wash with plenty of soap and water.

P304+P340: IF INHALED: Remove victim to fresh air and keep at rest in a position comfortable for breathing.

P305+P351+P338: IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing.

P337+313: If eye irritation persists get medical advice/attention.

Section 3: Composition and Information on Ingredients

Product Name & Other Names: Calcium stearate.

CAS Number: 1592-23-0

EINECS EC Number: 216-472-8

Section 4: First Aid Measures

Always seek medical advice after the first aid treatment.

Eye Contact: Flush eyes with plenty of water for at least 15 minutes, occasionally lifting the upper and lower lids. Get medical aid. Cold water may be used. Do not use an eye ointment. Seek medical attention.

Skin Contact: After contact of Calcium stearate with skin, wash immediately with plenty of water. Gently and thoroughly wash the contaminated skin with running water and non-abrasive soap. Be particularly careful to clean folds, crevices, creases, and groin. Cover the irritated skin with an emollient. If irritation persists, seek medical attention. Wash contaminated clothing before reusing.

Serious Skin Contact: Not available.

Inhalation: Allow the victim to rest in a well-ventilated area. Seek immediate medical attention.

Ingestion: Do not induce vomiting. Loosen tight clothing such as a collar, tie, belt, or waistband. If the victim is not breathing, perform mouth-to-mouth resuscitation. Seek immediate medical attention.

Section 5: Fire and Explosion Data

Flammability of the Product: It may be combustible at high temperature.

Products of Combustion: These products are carbon oxides (CO, CO2). Some metallic oxides.

Fire Fighting Media and Instructions:

SMALL FIRE: Use DRY chemical powder.

LARGE FIRE: Use water spray, fog or foam. Do not use solid water jet.

Use foam, carbon dioxide, or water spray when fighting fires involving this material.

Special Information: In the event of a fire, wear full protective clothing and NIOSH-approved self-contained breathing apparatus with full face piece operated in the pressure demand or other positive pressure mode. At high temperatures under fire conditions, it may produce toxic or irritating fumes. Fire-extinguishing work is done from the windward and the suitable fire-extinguishing method according to the surrounding situation is used.

Section 6: Accidental Release Measures

Personal precautions, protective equipment, and emergency procedures: Avoid breathing dust/fumes/gas/mist/vapors/spray. Use individual protective equipment (waterproof boots, suitable protective clothing, safety glasses, etc.). Do not approach facing the wind.

Environmental precautions: Do not let the product enter drains, soil, or water sources.

Methods and materials used for containment Cleanup procedures and Storage: Do not inhale dust, vapors, mist, or gas. Avoid dust formation. Contain spilled material. Cover with an inert, non-combustible absorbent material, (e.g. sand, earth, diatomaceous earth, vermiculite). Use a shovel to put the material into a convenient waste disposal container. Finish cleaning by spreading water on the contaminated surface and allow to evacuate as per law.

Section 7: Handling and Storage

Precautions for safe handling: Apply according to good manufacturing and industrial hygiene practices. Ensure proper ventilation. In case of insufficient ventilation, wear suitable respiratory equipment. Wash thoroughly after handling. Do not drink, eat, or smoke while handling. Avoid contact with skin, eyes, and clothing. Minimize dust generation. Avoid breathing dust/fumes/gas/mist/vapors/spray. Keep container tightly closed. Avoid ingestion and inhalation. Use individual protective equipment (waterproof boots, suitable protective clothing, safety glasses, etc.).

Conditions for safe storage, including any incompatibilities: Store in cool, dry, and ventilated area away from heat sources and protected from sunlight in tightly closed original container. Keep air contact to a minimum. Store protected from heat, sparks and ignition sources and incompatible materials. Avoid contact with skin and eyes. Avoid inhalation of dust/mist/vapor. Do not store with incompatible materials like strong oxidizing agents.

Section 8: Exposure Controls/Personal Protection

Engineering Controls: Use process enclosures, local exhaust ventilation, or other engineering controls to keep airborne levels below recommended exposure limits.

Ventilation System: A system of local and/or general exhaust is recommended to keep employee exposures as low as possible.

Personal Respirators (NIOSH Approved): For conditions of use where exposure to dust or mist is apparent and engineering controls are not feasible, a particulate respirator may be worn.

Skin Protection: Wear protective gloves and clean body-covering clothing.

Eye Protection: Use chemical safety goggles and/or full face shield where dusting or splashing of solutions is possible. Maintain eye wash fountain and quick-drench facilities in work area.

Other Control Measures: Maintain good housekeeping in work area. Handle in accordance with good industrial hygiene and safety practice.

Section 9: Physical and Chemical Properties

Physical state and appearance: White solid.

Odor: Not available.

Odor threshold: Not available.

pH: Not available.

Relative density: Not available.

Boiling Point: Decomposes.

Melting Point: 147 to 149 say 148C (298.4F).

Flash point: Not available.

Auto-ignition temperature: Not available.

Decomposition temperature: Not available.

Upper/lower flammability or explosive limits: Not available.

Vapor pressure: Not available.

Vapor density: Not available.

Evaporation rate: Not available.

Flammability (solid, gas): Not available.

Partition coefficient: n-octanol/water: Not available.

Solubility(ies): Not available.

Viscosity: Not available.

Section 10: Stability and Reactivity Data

Stability: Stable under normal conditions of use and storage.

Instability Temperature: Not available.

Incompatibility with various substances: Strong oxidizing agents.

Corrosivity: Non-corrosive in presence of glass.

Polymerization: No.

Section 11: Toxicological Information

Toxicity to Animals: LD50 Oral-Rat: >10g/kg.

Carcinogenicity: No component of this product present at levels greater than or equal to 0.1% is identified as probable or confirmed human carcinogen by IARC, ACGIH, OSHA and NTP.

Mutagenic Effects: Not available.

Developmental Toxicity: Not available.

Section 12: Ecological Information

Aquatic toxicity: NOEC: 2.2 mg/l (leuciscus idus)

Persistence and Degradability: No information available.

Mobility: No information available.

Bioaccumulation/ Accumulation: No information available.

Results of PBT and vPvB assessment: No data available for assessment.

Section 13: Disposal Considerations

Waste Disposal: Whatever cannot be saved for recovery or recycling should be managed in an appropriate and approved waste disposal facility.

Section 14: Transport Information

DOT USA, TDG Canada & ADR/RID Europe: Not controlled.

IMO/IMDG: Not controlled.

IATA/ICAO: Not controlled.

Section 15: Other Regulatory Information

USA:

SARA 311/312: See section 2.

California Proposition 65: This product does not contain any Proposition 65 chemicals

DISCLAIMER: The information and recommendations set forth herein are presented in good faith and believed correct as of the date hereof. It is compiled from various sources and it is not necessarily all inclusive nor fully adequate in every circumstance. In addition, these suggestions should not be confused with nor followed in violation of applicable laws, regulations, rules or insurance requirements applicable. This MSDS sheet is intended only as a guide to the appropriate precautionary handling of the material by a properly trained person using this product. Individuals receiving the information must exercise their independent judgment in determining its appropriateness for a particular purpose.

Anmol Chemicals & Pharmaceuticals Pvt. Ltd. is an off-shoot of Anmol Chemicals Taloja. It is located in MIDC Taloja and it is manufacturing pharmaceutical grades of API, Excepients, Food grade and Reagent grade chemicals. Anmol Chemicals & Pharmaceuticals Pvt. Ltd. is a several decades old group of companies, engaged in manufacturing, supplying, distributing, wholesale supplies for actual users, retail or small pack supplies for research and development chemicals, fine and speciality chemicals, pharmaceutical excipients, mineral fortifiers in chemically pure, Analytical reagent grade, IP BP USP Ph Eur EP JP and other pharmaceutical grade monograph including FCC Food grade chemicals and Nutraceuticals, Mineral Fortifiers at best prices.

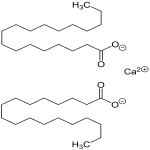

Calcium Stearate Structure

CAS Number 1592-23-0, Calcium Stearate Manufacturer Exporter

ANMOL CHEMICALS & PHARMACEUTICALS Pvt. Ltd.

India, USA, Europe, UAE

TELEPHONE: +912223770100

Navi Mumbai, INDIA

e-mail: info(At the rate i.e. @)anmol.org

Copyright. 25-nov-24

We manufacture:

Glacial Acetic Acid Manufacturer

Calcium Ascorbate or Ascorbic Acid Calcium Salt

Calcium Gluceptate or Calcium Glucoheptonate