CAS Number 1310-73-2, Caustic Soda or Sodium Hydroxide Pellets Powder Flakes Solution Lye USP NF IP EP BP Ph Eur Analytical Reagent FCC Food Grade Manufacturers Exporters

CAS Number 1310-73-2, Caustic Soda or Sodium Hydroxide Pellets Powder Flakes Solution Lye Manufacturer Exporter

For Properties Specifications of Caustic Soda or Sodium Hydroxide Pellets Powder Flakes Solution Lye Click Properties, Specifications of Caustic Soda or Sodium Hydroxide Pellets Powder Flakes Solution Lye Manufacturer.

For Uses of Caustic Soda or Sodium Hydroxide Click Uses of Caustic Soda or Sodium Hydroxide Manufacturer.

For For SDS MSDS Sheet of Caustic Soda or Sodium Hydroxide Click SDS Safety Data Sheet MSDS Sheet of Caustic Soda or Sodium Hydroxide Manufacturer.

The Properties and Specifications of Caustic Soda or Sodium Hydroxide:

Sodium Hydroxide BP Ph Eur Grade Specifications

Caustic Soda Pellets

Sodium Hydroxide

NaOH -- 40.00

DEFINITION

Content: 97.0 per cent to 100.5 per cent Sodium Hydroxide.

CHARACTERS

Appearance: White or almost white, crystalline masses, supplied as pellets, sticks or slabs, deliquescent, readily absorbing carbon dioxide.

Solubility: Very soluble in water, freely soluble in ethanol (96 per cent).

IDENTIFICATION

A. pH minimum 11.0.

B. 2 ml of solution S gives reaction of sodium.

TESTS

Solution S: Carry out the procedure described below with caution. Dissolve 5.0 g in 12 ml of distilled water. Add 17 ml of hydrochloric acid R1, adjust to pH 7 with 1 M hydrochloric acid and dilute to 50 ml with distilled water.

Appearance of solution: The solution is clear and colourless.

Dissolve 1.0 g in 10 ml of water.

Carbonates: Maximum 2.0 per cent, calculated as Na2CO3 as determined in the assay.

Chlorides: Maximum 50 ppm.

Sulphate: Maximum 50 ppm.

Iron: Maximum 10 ppm, determined on solution S.

Heavy metals: Maximum 20 ppm.

Sodium Hydroxide EP Grade:

Sodium Hydroxide EP Grade is also offered.

Sodium Hydroxide USP NF Grade Specifications

Sodium Hydroxide

NaOH 40.00

Caustic Soda Pellets

Sodium hydroxide CAS 1310-73-2

Sodium Hydroxide contains not less than 95.0 percent and not more than 100.5 percent of total alkali, calculated as NaOH, including not more than 3.0 percent of Na2CO3.

Caution—Exercise great care in handling Sodium Hydroxide, as it rapidly destroys tissues.

Identification: A solution (1 in 25) responds to the tests for Sodium.

Insoluble substances and organic matter: A solution (1 in 20) is complete, clear, and colorless to slightly colored.

Potassium: Acidify 5 mL of a solution (1 in 20) with 6 N acetic acid, then add 5 drops of sodium cobalt nitrite TS: no precipitate is formed.

Heavy metals: the limit is 0.003%.

Sodium Hydroxide FCC Food Grade Specifications

Caustic Soda Pellets

NaOH Formula weight 40.00

Sodium Hydroxide

INS: 524 CAS 1310-73-2

DESCRIPTION

Sodium Hydroxide occurs as white or nearly white pellets, flakes, sticks, fused masses, or other forms. Upon exposure to air it readily absorbs carbon dioxide and moisture. One gram dissolves in 1 mL of water. It is freely soluble in alcohol.

Function: pH control agent.

REQUIREMENTS

Identification: A 1:25 aqueous solution gives positive tests for Sodium.

Assay: Not less than 95.0% and not more than 100.5% of total alkali, calculated as NaOH.

Arsenic: Not more than 3 mg/kg.

Carbonate: (as Na2CO3) Not more than 3.0%.

Insoluble Substances and Organic Matter: Passes test.

Lead: Not more than 2 mg/kg.

Mercury: Not more than 0.1 mg/kg.

Sodium Hydroxide Analytical Reagent Grade Caustic Soda Pellets Specifications

Sodium Hydroxide

NaOH

Formula Weight 40.00

CAS Number 1310-73-2

REQUIREMENTS

Assay: 97.0% NaOH min

Sodium Carbonate: 1.0% Na2CO3 max

MAXIMUM ALLOWABLE

Chloride (Cl): 0.005%

Nitrogen compounds (as N): 0.001%

Phosphate (PO4): 0.001%

Sulfate (SO4): 0.003%

Ammonium hydroxide precipitate: 0.02%

Heavy metals (as Ag): 0.002%

Iron (Fe): 0.001%

Mercury (Hg): 0.1 ppm

Nickel (Ni): 0.001%

Potassium (K): 0.02%.

The Uses of Caustic Soda or Sodium Hydroxide:

Sodium Hydroxide may be used to produce soaps, rayon, paper, dyes, and petroleum products. Other tasks that may use sodium hydroxide include processing cotton fabric, metal cleaning and processing, oxide coating, electroplating, and electrolytic extraction. Sodium hydroxide is used in many industries: in the manufacture of pulp and paper, textiles, drinking water, soaps and detergents, and as a drain cleaner. It is used in pharmaceuticals, oil and gas fracturingand other industries.

The MSDS-SDS Hazard Statement of Caustic Soda or Sodium Hydroxide:

Sodium Hydroxide or Caustic Soda SDS, Safety Data Sheet

MSDS Sheet, Material Safety Data Sheet 25-Jan-23

Section 1: Product Identification

Product Name & Other Names: Caustic Soda or Sodium Hydroxide Solid, Flakes, Pellets.

CAS No.: 1310-73-2

EINECS EC Number: 215-185-5

Molecular Weight: 40.00

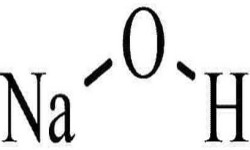

Chemical Formula: NaOH

Relevant uses and uses advised against (if any): Laboratory chemicals, Manufacture of substances. For Industrial use.

Section 2: Hazard Identification

GHS, Globally Harmonized System Classification in accordance with 29 CFR 1910

Classification according to Regulation (EC) No 1272/2008

Corrosive to Metals Category 1

Skin corrosion/irritation Category 1A, B, C

Hazardous to the aquatic environment, acute hazard Category 3

Labeling according to Regulation (EC) No 1272/2008

GHS Label Elements  Corrosive |

Signal Words: Danger

Hazard statements:

H290: May be corrosive to metals

H314: Causes severe skin burns and eye damage

H402: Harmful to aquatic life.

Precautionary statements:

P234: Keep only in original container.

P260: Do not breathe dust/fume/gas/mist/vapors/spray.

P264: Wash … thoroughly after handling.

P273: Avoid release to the environment.

P280: Wear protective gloves/protective clothing/eye protection/face protection.

P312: Call a POISON CENTER or doctor/physician if you feel unwell.

P362: Take off contaminated clothing and wash before reuse.

P301+330+331: IF SWALLOWED: Rinse mouth. Do NOT induce vomiting.

P303+361+353: IF ON SKIN (or hair): Remove/Take off immediately all contaminated clothing. Rinse skin with water/shower.

P305+351+338: IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses if present and easy to do – continue rinsing.

Section 3: Composition / Information on Ingredients

Product Name & Other Names: Caustic Soda or Sodium Hydroxide Solid, Flakes, Pellets.

CAS No.: 1310-73-2

EINECS EC Number: 215-185-5

Dilution, if any is with water.

Section 4: First Aid Measures

Always seek medical attention after first aid measures are provided.

Eye Contact: Check for and remove any contact lenses. In case of contact, immediately flush eye with plenty of water for at least 15 minutes. Cold water may be used. Get medical attention immediately.

Skin Contact: Immediately flush skin with plenty of water for at least 15 minutes while removing contaminated clothing and shoes. Call a physician, immediately. Wash clothing before reuse.

Ingestion: If swallowed, do not induce vomiting unless directed to do so by medical personnel. Never give anything by mouth to and unconscious person. Loosen tight clothing such as a collar, tie, belt, or waistband. Get medical attention immediately.

Medical Conditions generally Aggravated by Exposure: Repeated exposure of the eyes to a low level of Sodium hydroxide dust can produce eye irritation. Repeated skin exposure can produce local skin destruction, or dermatitis. Repeated inhalation of dust can produce varying degree of respiratory irritation or lung damage.

Section 5: Fire Fighting Measures

Flash Point: NA

Fire Extinguishing Media: Adapt extinguishing media to the environment. Use water spray, alcohol-resistant foam, dry chemical or carbon dioxide.

Special Fire Fighting Procedures: Wear self contained breathing apparatus for firefighting if necessary.

Unusual Fire and Explosion Hazards: Flammable hydrogen gas may be produced on prolong contact with metals such as aluminum, tin lead and zinc.

Hazardous combustion products: Oxides of sodium.

Section 6: Accidental Release Measures

Personal precautions, protective equipment, and emergency procedures: Avoid breathing dust/fumes/gas/mist/vapors/spray. Use individual protective equipment (waterproof boots, suitable protective clothing, safety glasses, etc.). Eliminate any ignition sources. Do not approach facing the wind.

Environmental precautions: Do not let the product enter drains, soil, or water sources.

Methods and materials used for containment Cleanup procedures and Storage: Do not inhale vapors, mist, or gas. Avoid dust formation. Contain spilled material. Cover with an inert, non-combustible absorbent material, (e.g. sand, earth, diatomaceous earth, vermiculite). Use a shovel to put the material into a convenient waste disposal container. Finish cleaning by spreading water on the contaminated surface and allow to evacuate as per law. Small quantities of liquid spill may be neutralize with acid solution.

Section 7: Handling and Storage

Precautions for safe handling: Apply according to good manufacturing and industrial hygiene practices. Ensure proper ventilation. In case of insufficient ventilation, wear suitable respiratory equipment. Wash thoroughly after handling. Do not drink, eat, or smoke while handling. Avoid contact with skin, eyes, and clothing. Minimize dust generation. Avoid breathing dust/fumes/gas/mist/vapors/spray. Keep container tightly closed. Avoid ingestion and inhalation. Use individual protective equipment (waterproof boots, suitable protective clothing, safety glasses, etc.).

Conditions for safe storage, including any incompatibilities: Store in cool, dry, and ventilated area away from heat sources and protected from sunlight in tightly closed original container. Keep air contact to a minimum. Store protected from heat, sparks and ignition sources and incompatible materials. Avoid contact with skin and eyes. Avoid inhalation of dust/mist/vapor. Do not store with incompatible materials like strong oxidizing agents, acids, chlorinated hydrocarbons, metals, and organic materials. Avoid moisture. Always add the caustic to water while stirring, never the reverse. Do not store with aluminum or magnesium.

Section 8: Exposure Controls / Personal Protection

Components with workplace control parameters

Derived No Effect Level (DNEL)

Application Area: Workers, Consumers

Exposure routes: Inhalation

Health effect Long-term local effects: 1 mg/m3

USA ACGIH: 2 mg/m³ ACGIH Ceiling (mg/m³)

USA OSHA: 2 mg/m³ OSHA PEL (TWA) (mg/m³)

British Columbia: 2 mg/m³ OEL Ceiling (mg/m³)

Engineering Controls Ventilation required: Sodium hydroxide should be handled or transferred in an approved fume hood or with adequate ventilation.

Personal Protection Equipment

Respiratory protection: If workplace exposure limit (s) of product or any component is exceeded (see TLV/PEL), a NIOSH/MSHA approved air supplied respirator is advised in absence of proper environmental control. OSHA regulations also permit other NIOSH/MSHA respirator (negative pressure type) under specified conditions (see your safety equipment supplier). Engineering and/or administrative controls should be implemented to reduce exposure.

Protective gloves: Nitrile or equivalent.

Skin protection: Impervious, protective clothing.

Eye protection: Safety glasses with side shields must be worn at all times.

Additional clothing and/or equipment: Eyewash and safety equipment should be readily available.

Section 9 Physical and Chemical Properties

Appearance and Physical State: White Solid (flakes, pellets, powder or granular)

Odor (threshold): Odorless.

Odor threshold: Not available.

pH: 13-14 at 50gm/liter

Relative density: around 2.13 for dry material.

Melting Point: 318C (604F)

Boiling Point: 1390.04C (2534.1F)

Flash point: Not available.

Auto-ignition temperature: Not available.

Decomposition temperature: Not available.

Upper/lower flammability or explosive limits: Not available.

Vapor pressure: Not available.

Vapor density: Not available.

Evaporation rate: Not available.

Flammability (solid, gas): Not available.

Partition coefficient: n-octanol/water: Not available.

Solubility in Water: Soluble.

Viscosity: Not available.

Section 10: Stability and Reactivity

Stability: Sodium hydroxide is stable under ordinary conditions of use and storage. Very hygroscopic. Absorbs atmospheric CO2.

Reactivity: Exothermic reaction with water. Violent exothermic reaction with strong acids. Reacts with some metals to release hydrogen.

Conditions to Avoid: Contact with moisture may generate sufficient heat to ignite surrounding combustible material.

Materials to Avoid (Incompatibility): Water, acids, chlorinated hydrocarbons, oxidizing agents, metals and organic materials.

Hazardous Decomposition Products: None indicated.

Hazardous Polymerization: Will not occur.

Section 11: Toxicological Information

Results of component toxicity test performed:

1350 mg/kg skin-rabbit LD50;

104-340 mg/kg oral-rat LD50;

40 mg/kg intra peritoneal-mouse

LD50; 500 mg/kg oral-rabbit LDLo

This product is not classifiable as to its carcinogenicity based on its IARC, ACGIH, NTP, or EPA classification.

Tests on laboratory animals indicate material may produce adverse mutagenic effects.

Human experience: Extremely hazardous in case of eye contact ( corrosive). Causes severe eye burns. Extremely hazardous in case of skin contact (corrosive). Skin contact produces severe burns. Hazardous in case of skin contact (permeator). Extremely hazardous in case of inhalation (lung corrosive). Hazardous in case of inhalation. Extremely hazardous in case of ingestion. May be fatal if swallowed. This product does not contain any compounds listed by NTP or IARC or regulated by OSHA as a carcinogen.

Section 12: Ecological Information

Toxicity to fish:

LC50 - Gambusia affinis (Mosquito fish) - 125 mg/l - 96 h

LC50 - Oncorhynchus mykiss (rainbow trout) - 45,4 mg/l - 96 h

Toxicity to daphnia and other aquatic invertebrates: Immobilization EC50 - Daphnia - 40,38 mg/l - 48 h

This substance does not meet the criteria for classification as PBT or vPvB.

Section 13 Disposal Considerations

RCRA 40 CFR 261 Classification: Material does not have an EPA Waste Number and is not a listed waste. Federal, State, and local laws governing disposal of materials can differ. Ensure proper disposal compliance with proper authorities before disposal.

Section 14: Transportation Information

USA DOT Information:

Proper shipping name: Sodium Hydroxide, solid

Hazard Class: 8

Packaging group: II

UN Number: UN1823

IATA:

Proper shipping name: Sodium Hydroxide, solid

Hazard Class: 8

Packing group: II

UN Number: UN1823

IMO:

Proper shipping name: Sodium Hydroxide, solid

Class: 8

UN Number: UN1823

Packing group: II

EMS: ND

MFAG: ND

Marine Pollutant: No

ADR/RID:

UN Number: 1823

Description of the goods: Sodium Hydroxide

Packaging group: II

Hazard identification No: 80

Hazard label: 8

Environmentally Hazardous: No

Section 15: Regulatory Information

USA:

SARA 311/312: No products were found.

California Proposition 65: Not listed.

Section 16: Other Information

Disclaimer:

******************************

Our company provides this Caustic Soda Sodium hydroxide MSDS sheet contained herein in good faith but makes no representation as to its comprehensiveness or accuracy. This Sodium Hydroxide MSDS sheet is intended only as a guide to the appropriate precautionary handling of the material by a properly trained person using this product. Individuals receiving the information must exercise their independent judgment in determining its appropriateness for a particular purpose.

******************************

Anmol Chemicals & Pharmaceuticals Pvt. Ltd. is an off-shoot of Anmol Chemicals Taloja. It is located in MIDC Taloja and it is manufacturing pharmaceutical grades of API, Excepients, Food grade and Reagent grade chemicals. Anmol Chemicals & Pharmaceuticals Pvt. Ltd. is a several decades old group of companies, engaged in manufacturing, supplying, distributing, wholesale supplies for actual users, retail or small pack supplies for research and development chemicals, fine and speciality chemicals, pharmaceutical excipients, mineral fortifiers in chemically pure, Analytical reagent grade, IP BP USP Ph Eur EP JP and other pharmaceutical grade monograph including FCC Food grade chemicals and Nutraceuticals, Mineral Fortifiers at best prices.

Caustic Soda or Sodium Hydroxide Pellets Powder Flakes Solution Structure

CAS Number 1310-73-2, Caustic Soda or Sodium Hydroxide Pellets Powder Flakes Solution Lye Manufacturer Exporter

ANMOL CHEMICALS & PHARMACEUTICALS Pvt. Ltd.

India, USA, Europe, UAE

TELEPHONE: +912223770100

Navi Mumbai, INDIA

e-mail: info(At the rate i.e. @)anmol.org

Copyright. 23-nov-24

We manufacture:

Glacial Acetic Acid Manufacturer

Ammonia Solution Concentrated or Ammonium Hydroxide Solution

Dihydroxyaluminum Aminoacetate

Dihydroxyaluminum Sodium Carbonate

Nebivolol Hydrochloride or Nebivolol HCl