CAS Number 27216-37-1 or 126-13-6 or 123-13-6, Sucrose Acetate Isobutyrate or Sucrose acetoisobutyrate or SAIB or Sucrose diacetate hexaisobutyrate USP NF BP Ph Eur Analytical Reagent FCC Food Grade Manufacturers Exporters

CAS Number 27216-37-1 or 126-13-6 or 123-13-6, Sucrose Acetate Isobutyrate or Sucrose acetoisobutyrate or SAIB or Sucrose diacetate hexaisobutyrate Manufacturer Exporter

For Properties Specifications of Sucrose Acetate Isobutyrate or Sucrose acetoisobutyrate or SAIB or Sucrose diacetate hexaisobutyrate Click Properties, Specifications of Sucrose Acetate Isobutyrate or Sucrose acetoisobutyrate or SAIB or Sucrose diacetate hexaisobutyrate Manufacturer.

For Uses of Sucrose Acetate Isobutyrate or Sucrose acetoisobutyrate or SAIB or Sucrose diacetate hexaisobutyrate Click Uses of Sucrose Acetate Isobutyrate or Sucrose acetoisobutyrate or SAIB or Sucrose diacetate hexaisobutyrate Manufacturer.

For For SDS MSDS Sheet of Sucrose Acetate Isobutyrate or Sucrose acetoisobutyrate or SAIB or Sucrose diacetate hexaisobutyrate Click SDS Safety Data Sheet MSDS Sheet of Sucrose Acetate Isobutyrate or Sucrose acetoisobutyrate or SAIB or Sucrose diacetate hexaisobutyrate Manufacturer.

The Properties and Specifications of Sucrose Acetate Isobutyrate or Sucrose acetoisobutyrate or SAIB or Sucrose diacetate hexaisobutyrate:

Sucrose Diacetate Hexaisobutyrate USP Grade Specifications:

C40H62O19 --- 846.92

α-D-Glucopyranoside, 6-O-acetyl-1,3,4-tris-O-(2-methyl-1-oxopropyl)-β-D-fructofuranosyl, 6-acetate 2,3,4-tris(2-methylpropanoate);

6-O-Acetyl-1,3,4-tri-O-isobutyryl-β-D-fructofuranosyl 6-Oacetyl-2,3,4-tri-O-isobutyryl-α-D-glucopyranoside CAS 126-13-6.

DEFINITION

Sucrose Diacetate Hexaisobutyrate consists of a mixture of sucrose esters of acetic and isobutyric acid, with sucrose diacetate hexaisobutyrate being the predominant sucrose ester. It is produced through the controlled esterification of sucrose with acetic anhydride and isobutyric anhydride.

IDENTIFICATION

A. SPECTROSCOPIC IDENTIFICATION TESTS: Infrared Spectroscopy.

B. It meets the requirements in the test for Saponification Value under Specific Tests.

ASSAY

Acceptance criteria: 98.8%–101.9%

Fats & Fixed Oils: Procedures, Acid Value

Analysis: Add 100 mL of acetone and 0.5 mL of bromothymol blue TS to a 500-mL Erlenmeyer flask. While stirring, titrate the solvent to a bromothymol blue endpoint, with 0.05 N sodium hydroxide. Place the flask with the blanked solvent on a balance and tare. Add between 8–12 g of sample into the flask. [NOTE: The sample needs to be heated first to become a pourable liquid.1 ] The solution will turn yellow if acid is present. If 12 g of added sample does not turn the solution yellow, additional sample may be added up to 100 g by increasing the weight incrementally. If the blue color of the solution is not changed by 100 g of sample after mixing, report the acid value to less than 0.006 (reporting limit). Swirl the contents of the flask to mix. Heat if necessary to dissolve the sample. If heating is required, allow the solution to cool to room temperature before titration. While stirring, titrate the sample with 0.05 N sodium hydroxide to the same blue endpoint as the blank.

Acceptance criteria: NMT 0.2

Fats & Fixed Oils: Procedures, Saponification Value

Analysis: Weigh accurately about 1.5 g of Sucrose Diacetate Hexaisobutyrate directly into a tared 500-mL Erlenmeyer flask. Accurately dispense or pipet 50.0 mL of 0.5 N alcoholic potassium hydroxide VS into the 500-mL Erlenmeyer flask containing the sample and also into a second 500-mL Erlenmeyer flask to be used for the blank. Add a couple of boiling chips to each flask. Place each flask on a hot plate and connect the flasks to the reflux condensers, which are cooled with water. Reflux the solutions for approximately 1 h. Allow the flasks to cool, then wash down each condenser with approximately 50 mL of water. After the condensers drain, remove the flasks from the condensers. Add approximately 0.2 mL or 10 drops of PhPh to each flask. Titrate the blank and sample solutions with 0.5 N hydrochloric acid until the pink color disappears.

Acceptance criteria: 524–540.

Water Determination: NMT 0.5%

Specifications of Sucrose Acetate Isobutyrate FCC Food Grade:

C40H62O19 Formula weight 846.9 (range 832 to 856)

INS: 444 CAS 27216-37-1

CAS 123-13-6

DESCRIPTION

Sucrose Acetate Isobutyrate occurs as a clear, pale yellow, viscous liquid. It consists of a mixture of sucrose esters of acetic and isobutyric acid, with sucrose diacetate hexaisobutyrate being the predominant sucrose ester. It is produced through the controlled esterification of sucrose with acetic anhydride and isobutyric anhydride. It is very soluble in essential oils such as orange oil, soluble in ethanol and in ethyl acetate, and very slightly soluble in water.

Function: Stabilizer.

REQUIREMENTS

Identification: Identify Sucrose Acetate Isobutyrate by comparing its infrared absorption spectrum with a typical spectrum as shown in the section on Infrared Spectra, using the same test conditions as specified therein.

Assay: Not less than 98.8% and not more than 101.9% of C40H62O19.

Acid Value: Not more than 0.2.

Lead: Not more than 1 mg/kg.

Saponification Value: Not less than 524 and not more than 540.

The Uses of Sucrose Acetate Isobutyrate or Sucrose acetoisobutyrate or SAIB or Sucrose diacetate hexaisobutyrate:

Sucrose acetate isobutyrate (SAIB), a mixture of esters of sucrose with a composition approximating the name sucrose diacetate hexaisobutyrate, has been used for over 30 yr in many countries as a 'weighting' or 'density-adjusting' agent in non-alcoholic carbonated and non-carbonated beverages. It is used in Beverage emulsions, Color cosmetics and skin care, Flavorings, Fragrance fixative, Hair care, etc. It is also used in inks, coatings. Sucrose acetoisobutyrate or Sucrose acetate isobutyrate or Sucrose Diacetate Hexaisobutyrate or SAIB is an emulsifier and has E number E444. In the United States, SAIB is categorized as generally recognized as safe (GRAS) as a food additive in cocktail mixers, beer, malt beverages or wine coolers.

The MSDS-SDS Hazard Statement of Sucrose Acetate Isobutyrate or Sucrose acetoisobutyrate or SAIB or Sucrose diacetate hexaisobutyrate:

Sucrose acetate isobutyrate or Sucrose acetoisobutyrate or SAIB Sucrose Diacetate Hexaisobutyrate SDS Safety Data Sheet

MSDS Sheet, Material Safety Data Sheet 30-Jan-23

Section 1 - Chemical Product and Company Identification

Product Name & Other Names:Sucrose acetate isobutyrate or Sucrose acetoisobutyrate or Sucrose Diacetate Hexaisobutyrate or SAIB.

CAS Number: 27216-37-1 or 126-13-6

EINECS EC Number: 204-771-6

Molecular Formula: C40H62O19

Molecular Weight: 846.92

Relevant uses and uses advised against (if any): Industrial Manufacturing.

Section 2 - Hazards Identification

GHS, Globally Harmonized System Classification in accordance with 29 CFR 1910

Classification according to Regulation (EC) No 1272/2008

Not a hazardous substance or mixture according to Regulation (EC) No. 1272/2008.

This substance is not classified as dangerous according to Directive 67/548/EEC.

Labeling according to GHS USA & Regulation (EC) No 1272/2008

GHS Label Elements NONE |

Precautionary statements:

P261: Avoid breathing dust/fume/gas/mist/vapors/spray.

P262: Do not get in eyes, on skin, or on clothing.

P281: Use personal protective equipment as required.

P302+P352 - IF ON SKIN: Wash with plenty of soap and water.

P304 + P340 - IF INHALED: Remove victim to fresh air and keep at rest in a position comfortable for breathing.

P305 + P351 + P338 - IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing.

P337+313: If eye irritation persists get medical advice/attention.

Section 3 - Composition, Information on Ingredients

Product Name & Other Names:Sucrose acetate isobutyrate or Sucrose acetoisobutyrate or Sucrose Diacetate Hexaisobutyrate or SAIB.

CAS Number: 27216-37-1 or 126-13-6

EINECS EC Number: 204-771-6

Section 4 - First Aid Measures

Always consult a physician after the first aid is given.

Eyes: Immediately flush eyes with plenty of water for at least 15 minutes, occasionally lifting the upper and lower eyelids. Get medical aid. Do NOT allow victim to rub or keep eyes closed.

Skin: Flush skin with plenty of soap and water for at least 15 minutes while removing contaminated clothing and shoes. Get medical aid if irritation develops or persists. Wash clothing before reuse.

Ingestion: Do NOT induce vomiting. If victim is conscious and alert, give 2-4 cup full of milk or water. Never give anything by mouth to an unconscious person. Get medical aid.

Inhalation: Remove from exposure to fresh air immediately. If breathing is difficult, give oxygen. Get medical aid. Do NOT use mouth-to-mouth resuscitation. If breathing has ceased apply artificial respiration using oxygen and a suitable mechanical device such as a bag and a mask.

Section 5 - Fire Fighting Measures

General Information: As in any fire, wear a self-contained breathing apparatus in pressure-demand, MSHA/NIOSH (approved or equivalent), and full protective gear. During a fire, irritating and highly toxic gases may be generated by thermal decomposition or combustion.

Flammability: Flammable. Explosive in presence of oxidizing materials.

Extinguishing Media: Use Water, dry chemical powder, alcohol foam, water spray or fog. Cool containing vessels with water jet in order to prevent pressure build-up, auto-ignition or explosion.

Section 6 - Accidental Release Measures

Personal precautions, protective equipment and emergency procedures: Avoid breathing dust/fumes/gas/mist/vapors/spray. Use individual protective equipment (waterproof boots, suitable protective clothing, safety glasses, etc.). Do not approach facing the wind.

Environmental precautions: Do not let the product enter drains, soil or water sources.

Methods and materials used for containment Cleanup procedures and Storage: Contain spilled material. Cover with an inert, non-combustible absorbent material, (e.g. sand, earth, diatomaceous earth, vermiculite). Vacuum or sweep-up and remove to an approved disposal container. Use proper personal protective equipment. Restrict unprotected personnel from the area. Remove all ignition sources and ventilate area. Use water spray to dilute spill to a non-flammable mixture. Avoid runoff into storm sewers and ditches which lead to waterways. Wash area with soap and water. Use water spray to disperse the gas/vapor.

Section 7 - Handling and Storage

Precautions for safe handling: Avoid ingestion and inhalation. Do not allow contact with heat. Apply according to good manufacturing and industrial hygiene practices. Ensure proper ventilation. Wash thoroughly after handling. Do not drink, eat or smoke while handling. Avoid contact with skin, eyes and clothing. Minimize dust generation. Avoid breathing dust/fumes/gas/mist/vapors/spray. Keep container tightly closed. Avoid ingestion and inhalation. Use individual protective equipment (waterproof boots, suitable protective clothing, safety glasses, etc.).

Conditions for safe storage, including any incompatibilities: Store in cool, dry and ventilated area away from heat sources and protected from sunlight in tightly closed original container. Keep air contact to a minimum. Do not leave the material container open. Store protected from heat, sparks and ignition sources and incompatible materials. Avoid contact with skin and eyes. Avoid inhalation of dust/mist/vapor. Do not store with incompatible materials like oxidizing agents.

Section 8 - Exposure Controls, Personal Protection

Airborne Exposure Limits: Not established.

Ventilation System: A system of local and/or general exhaust is recommended to keep employee exposures as low as possible.

Personal Respirators (NIOSH Approved): For conditions of use where exposure to dust or mist is apparent and engineering controls are not feasible, a particulate respirator (NIOSH type N95 or better filters) may be worn.

Skin Protection: Wear impervious protective clothing, including boots, gloves, lab coat, apron or coveralls, as appropriate, to prevent skin contact.

Eye Protection: Use chemical safety goggles and/or full face shield where dusting or splashing of solutions is possible. Maintain eye wash fountain and quick-drench facilities in work area.

Other Control Measures: Maintain good housekeeping in work area. Handle in accordance with good industrial hygiene and safety practice..

Section 9 - Physical and Chemical Properties

Appearance: Colorless to faint yellow viscous liquid.

Odor: Almost odorless.

Odor threshold: Not available.

pH: Not available.

Relative density: 1.15

Boiling Point: 288C literature.

Melting Point: -7C.

Flash point: Not available.

Auto-ignition temperature: Not available.

Decomposition temperature: Not available.

Upper/lower flammability or explosive limits: Not available.

Vapor pressure: Not available.

Vapor density: Not available.

Evaporation rate: Not available.

Flammability (solid, gas): Not available.

Partition coefficient: n-octanol/water: Not available.

Solubility: Insoluble in water. Soluble in most organic solvents.

Viscosity: Not available.

Section 10 - Stability and Reactivity

Chemical Stability: Stable under normal temperatures and pressures.

Conditions to Avoid: Incompatible materials, exposure to heat, spark.

Incompatibilities with Other Materials: Oxidizing agents.

Hazardous Decomposition Products: Carbon monoxide, irritating and toxic fumes and gases, carbon dioxide.

Hazardous Polymerization: Will not occur.

Section 11 - Toxicological Information

Acute toxicity: LD50 Oral Rat: 25600 mg/kg.

Carcinogenicity: None of the components of this formulation are listed as a carcinogen by IARC, NTP or OSHA..

Mutagenic Effects: Not available.

Developmental Toxicity: Not available.

Reproductive Effects: No information available.

Section 12 - Ecological Information

Toxicity to fish: LC50 (Pimephales promelas (fathead minnow)): > 1.82 mg/l Exposure time: 96 h.

Environmental Fate: No information available.

Persistence and Degradability: No information available.

Mobility: No information available.

Bioaccumulation/ Accumulation: No information available.

Results of PBT and vPvB assessment: No data available for assessment.

Section 13 - Disposal Considerations

Whatever cannot be saved for recovery or recycling should be managed in an appropriate and approved waste disposal facility. Processing use or contamination of this product may change the waste management options. State and local disposal regulations may differ from federal disposal regulations. Dispose of container of Glycerin and unused contents in accordance with law.

Section 14 - Transport Information

DOT USA, TDG Canada & ADR/RID Europe: Not controlled.

IMDG/IMO: Not controlled.

IATA: Not controlled.

Section 15 - Regulatory Information

USA:

SARA 311/312 Hazards: See section 2.

California Prop. 65 Components: Not listed.

Disclaimer:

**************************

Our company provides this MSDS sheet in good faith but makes no representation as to its comprehensiveness or accuracy. This SDS sheet is intended only as a guide to the appropriate precautionary handling of the material by a properly trained person using this product. The above information has been compiled from various sources and has the possibility of discrepancy and being out-dated information. Individuals receiving the information must exercise their independent judgment and do further search in determining its appropriateness for a particular purpose. In no case shall our company be liable to loss or damages by the product user.

**************************

Anmol Chemicals & Pharmaceuticals Pvt. Ltd. is an off-shoot of Anmol Chemicals Taloja. It is located in MIDC Taloja and it is manufacturing pharmaceutical grades of API, Excepients, Food grade and Reagent grade chemicals. Anmol Chemicals & Pharmaceuticals Pvt. Ltd. is a several decades old group of companies, engaged in manufacturing, supplying, distributing, wholesale supplies for actual users, retail or small pack supplies for research and development chemicals, fine and speciality chemicals, pharmaceutical excipients, mineral fortifiers in chemically pure, Analytical reagent grade, IP BP USP Ph Eur EP JP and other pharmaceutical grade monograph including FCC Food grade chemicals and Nutraceuticals, Mineral Fortifiers at best prices.

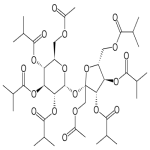

Sucrose Acetate Isobutyrate or Sucrose acetoisobutyrate or SAIB or Sucrose diacetate hexaisobutyrate Structure

CAS Number 27216-37-1 or 126-13-6 or 123-13-6, Sucrose Acetate Isobutyrate or Sucrose acetoisobutyrate or SAIB or Sucrose diacetate hexaisobutyrate Manufacturer Exporter

ANMOL CHEMICALS & PHARMACEUTICALS Pvt. Ltd.

India, USA, Europe, UAE

TELEPHONE: +912223770100

Navi Mumbai, INDIA

e-mail: info(At the rate i.e. @)anmol.org

Copyright. 11-dec-24

We manufacture:

Glacial Acetic Acid Manufacturer

Dihydroxyaluminum Aminoacetate

TBHQ Tertiary Butylhydroquinone